June 24, 2024

By: PhoenixBizz Staff Writer

PhoenixBizz is a division of Sofvue, LLC

Printed with permission of Data Titan and Sofvue LLC

The automotive manufacturing market has witnessed several innovations in recent years. From autopilot vehicles to a surge in electric vehicles, the industry has progressed significantly. Companies in this sector undertake numerous time-consuming operations. Fortunately, technology can simplify and expedite workflows, ensuring timely completion.

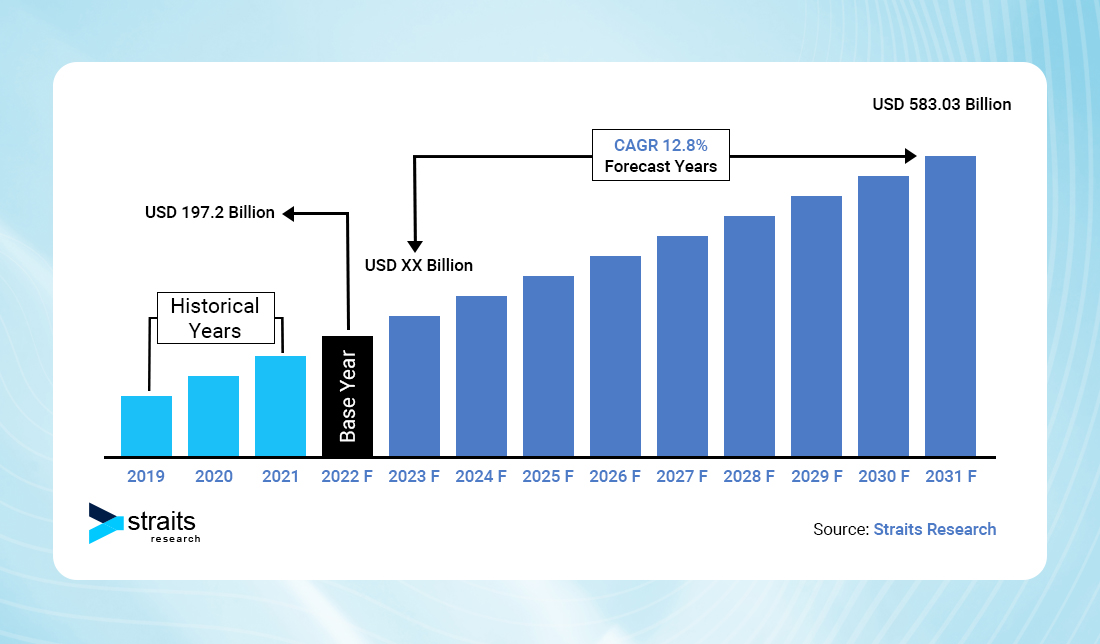

Mobile application development services are increasingly being adopted by businesses to enhance efficiency. According to a report by Statista, the global mobile app development market is projected to reach $583.03 billion by 2030. This impressive figure underscores the popularity of mobile apps in today's tech-driven world.

That said, if you are looking for ways to increase the efficiency of your automotive manufacturing company by using the latest technologies in app development, then this article provides insightful information for you. We have compiled the most practical and reliable details on high-end technologies that can be integrated into an automotive manufacturing app.

How are Mobile Apps being used in the Automotive Manufacturing Sector?

Automotive manufacturing companies have various departments dedicated to different functions. A mobile app equipped with the latest technologies can streamline day-to-day tasks within these companies. In today's digital age, relying on manual processes is inefficient and prone to errors, which is why companies are increasingly adopting innovative solutions. Here’s how mobile applications can be utilized in various business segments within automotive manufacturing:

#1. Production Management

Automate scheduling, monitor production lines, and track inventory in real-time.

#2. Quality Control

Implement AI-driven inspection systems to detect defects and ensure high standards.

#3. Supply Chain Coordination

Use blockchain for transparent tracking of parts and materials from suppliers.

#4. Maintenance

Employ IoT for predictive maintenance of machinery, reducing downtime.

#5. Human Resources

Facilitate workforce management with tools for scheduling, training, and communication.

#6. Customer Interaction

Enhance customer service and engagement through user-friendly interfaces and real-time support.

Must Read: How Data-Centric Mobile Apps Are Impacting Automotive Manufacturing In 2024

Safety and Quality Control (QC)

Driver and passenger safety is the top priority for automotive manufacturing companies. These firms can automate the entire process using a mobile app that sends timely alerts to teams whenever a vehicle fails a safety test. The app provides a detailed analysis of the vehicle, helping identify key weak points.

Companies can also use AI and sensors to detect errors or defects at the earliest production stages, ensuring the design remains robust and guaranteeing overall safety. This proactive approach enhances the reliability and safety of vehicles, aligning with the industry's commitment to protecting drivers and passengers.

Compliance with Safety and Legal Regulations

All vehicles and car components manufactured by your company must meet stringent safety and legal standards to avoid hefty penalties. Using mobile apps for automotive manufacturing helps ensure compliance with these standards efficiently. The app monitors your company's work processes, vehicles, components, and various other aspects.

In case of any shortfalls, the app provides a comprehensive report, enabling you to study the issues and find viable solutions to meet all quality and safety standards. This proactive monitoring and reporting help maintain compliance and uphold the highest levels of safety and quality in your manufacturing operations.

Supply Chain Management

A mobile application can provide stakeholders with a real-time view of the supply chain, enabling them to track inventories, monitor shipments, and communicate with suppliers. It can also expedite the authorization process for purchase orders, simplifying procurement procedures. Supply chain management operations are challenging, requiring constant monitoring of inventory levels and shipments to prevent delays. A mobile app streamlines these processes by offering clear visibility, making supply chain management quicker and more efficient.

Trending Technologies using Automotive Mobile Apps

Top-tier technologies such as artificial intelligence, machine learning, data analytics, and robotics have revolutionized the automotive manufacturing process. These advancements are also shaping the development of mobile apps for automotive manufacturing businesses. Innovations like smart cars, sensor-driven vehicle components, and other cutting-edge technologies are elevating user experience to new heights. Here is a list of some remarkable technologies currently trending in the automobile manufacturing industry:

1. Artificial Intelligence (AI)

AI is used for predictive maintenance, quality control, and optimizing production schedules.

2. Machine Learning (ML)

ML algorithms help in analyzing vast amounts of data to improve decision-making and process efficiency.

3. Data Analytics

Advanced analytics provide insights into production processes, supply chain management, and customer preferences.

4. Robotics

Robotics enhance precision and efficiency in manufacturing, from assembly lines to quality inspections.

5. Smart Cars

Vehicles equipped with advanced sensors and connectivity features offer improved safety, convenience, and user experience.

6. Sensor-Driven Components

Sensors monitor vehicle performance and detect potential issues, ensuring timely maintenance and safety.

7. Internet of Things (IoT)

IoT enables real-time monitoring and control of manufacturing equipment and processes.

8. Augmented Reality (AR)

AR is used for training, remote assistance, and enhancing the design and manufacturing process.

Internet of Things for Interconnectivity

Internet of Things (IoT)-based mobile apps are crucial for enhancing interconnectivity within automotive production units. Transitioning from an offline system to an IoT-based system involves integrating IoT sensors and devices into manufacturing components, allowing for optimal real-time monitoring of machinery, inventory levels, and production processes. This integration leads to improved productivity, fewer outages, and higher levels of proactive maintenance, ultimately reducing the costs associated with service disruptions.

In addition, IoT-enabled software ensures smooth information flow and data exchange between various stages of the production process. This interconnectedness leads to connected manufacturing and unified work across departments, which offers several key advantages: The improved interconnectivity and real-time data provided by IoT systems empower companies to compete more effectively in sophisticated markets. Efficient data exchange ensures that resources are utilized more effectively, minimizing waste and maximizing productivity. The streamlined operations and unified workflows enabled by IoT software help companies stay ahead of the competition.

Artificial intelligence

The line between AI and algorithms is rapidly disappearing, and no industry remains untouched by the AI revolution. Companies are leveraging this powerful technology to achieve remarkable business results, and the automotive manufacturing industry is no exception. Here are a few examples explaining how AI is changing the automotive manufacturing industry:

➔ Predictive Maintenance: AI algorithms process data from IoT sensors to forecast equipment breakdowns before they occur, minimizing downtime and optimizing production schedules.

➔ Quality Control: AI-enabled continuous image recognition and machine learning algorithms detect defects in real-time during production, ensuring high-quality products and reducing the need for rework.

➔ Supply Chain Optimization: AI analyzes past data and market trends to manage inventory levels, time logistics, and reduce costs, ensuring all components are ready and avoiding stockouts.

➔ Enhanced Safety: AI-powered mobile apps monitor worker safety, detect hazards, and trigger alerts to prevent accidents on the factory floor.

Human Machine Interface Technology

Automotive companies are heavily investing in Human-Machine Interface (HMI) technologies, and for good reasons. HMI technology enhances mobile apps with user-friendly interfaces, ensuring employees face no challenges while using them.

➔ Real-Time Monitoring: HMI technology enables real-time monitoring of equipment, manufacturing processes, and machinery. By adding a tracking feature to the app using HDMI technology, managers and concerned employees can closely track various manufacturing operations.

➔ Support for R&D Departments: HMI simplifies complex data and presents it in user-friendly formats such as graphs, charts, and dashboards, aiding research and development efforts.

➔ Enhanced Quality Control: HMI works alongside IoT technology to predict maintenance needs, boosting the quality control process. This integration promotes a safe and secure working environment for workers and employees.

How Modern Features Streamline Automotive Manufacturing

The best decision you can make for your automotive manufacturing business is to develop a mobile app. These apps come with various features designed to perform numerous tasks, making it essential to shortlist the best specifications through thorough research. Here are the top features to consider adding to your automotive manufacturing app:

➤ Diagnostic and Monitoring Feature

The app should include a tracking and monitoring feature to help concerned departments oversee various business aspects. Ensuring all vehicle components are in optimal condition before shipment is crucial for conducting proper quality checks. The app can send quick alerts to those responsible for quality checks, allowing them to take necessary steps to address issues or damages promptly.

➤ Maintenance Tracker

Timely maintenance of machinery and equipment is vital in an automotive manufacturing company. Ignoring periodic services can lead to equipment malfunctions, jeopardizing worker safety. The app should track maintenance appointments and notify the concerned teams in advance, ensuring machinery stays in top condition and delivers optimal results.

➤ Testing Feature

Automotive manufacturing companies frequently produce modern designs for vehicle components. These prototypes must be tested before progressing to the production stage. A testing feature on the mobile app should contain all data and information related to various tests for specific components. Employees or testers can input test results and other details into the app, making the information accessible to everyone.

➤ Warranty Tracker

Managing heavy machinery involves significant investment. The app should include a section that tracks the warranty periods for all machinery and tools, ensuring the company operates at optimal levels. If any equipment fails within the warranty period, it can be repaired or replaced for free, protecting your investment.

Other Mobile App Considerations to Know Regarding Automotive Manufacturing Workflow

When investing in a mobile app for your automotive manufacturing business, it's crucial to keep several important factors in mind. A mobile app encompasses various aspects such as UI/UX design, cross-device compatibility, and data security. Let's discuss in detail everything you should consider:

➤ UI/UX Design

The user interface (UI) and user experience (UX) design of the app are critical. Even though the app will be used by your employees, it should be intuitive and user-friendly. Complex designs can hinder productivity, as employees perform multiple tasks daily and should not struggle with understanding the app. The app should exist to simplify their work, not complicate it.

➤ Cross-Device Compatibility

Ensure the app is accessible on all platforms, including Android and iOS. This guarantees consistent and smooth functioning across different devices and operating systems. A single codebase that is compatible with various platforms saves time and money in development. Consistent user experience across devices ensures all employees can access the app regardless of the device they use. Additionally, forward compatibility allows the app to adapt to new devices and platforms, ensuring it remains relevant in the ever-evolving tech world.

➤ Data Security

Effective data security is paramount to prevent unauthorized access, data breaches, and cybercriminal activities. As an automotive manufacturing company, you handle highly sensitive data. Compliance with data protection regulations, such as the California Consumer Privacy Act (CCPA), is vital to avoid legal sanctions. Secure apps not only prevent financial losses but also protect against reputational damage. Prioritizing data security is essential for long-term app functionality and user satisfaction.

By considering these factors—UI/UX design, cross-device compatibility, and data security—you can ensure that the mobile app development process meets the needs of your automotive manufacturing business, enhances productivity, and protects valuable data.

Read More: How Autonomous Vehicles and Mobile Apps Are Driving Innovation with AI

Conclusion

The automotive industry is increasingly embracing tech-driven manufacturing mobile apps. While there is still room for more innovation, investing in this technology is a wise decision. Automobile giants are incorporating high-end technologies to further innovate the sector, from using big data in car systems to employing cloud computing for data storage. Manufacturing companies are transitioning to a fully digital world.

Partner with PhoenixBizz for High-End Mobile App Development

Are you looking for a trusted company to develop a highly responsive mobile app for your automotive manufacturing business? PhoenixBizz offers reliable and advanced mobile app development services for Arizona manufacturers. As a division of Sofvue LLC, we bring an impressive two decades of industry experience to the table. Our team of trained specialists, developers, coders, and designers collaborate to craft optimized and ROI driven software solutions.

Comprehensive Mobile App Development Services

We build custom mobile applications for businesses across various industries. Our services include:

✅ UI/UX Design: Creating intuitive and user-friendly designs that enhance the user experience.

✅ App Development: Developing robust and scalable mobile applications tailored to your specific business needs.

✅ App Testing: Conducting thorough testing to ensure the app functions flawlessly across all devices and platforms.

✅ App Launch: Managing the entire launch process to ensure a smooth deployment.

Let PhoenixBizz serve as you customer software and mobile app partner. Contact PhoenixBizz at 623-845-2747. Let’s meet, have a cup of coffee and discuss how to make your next great idea a reality.

RE: 11802

Citations:

Statista: https://straitsresearch.com/report/mobile-app-development-market